Environment

Please click on the tiles below for more information about Essential’s targeted environmental initiatives.

Download the ReportEnvironmental Stewardship and Management System

Environmental Stewardship

At Essential, our missions to sustain life and improve economic prosperity by safely and reliably delivering Earth’s most essential resources to our customers and communities fuels everything we do. We have taken these commitments seriously for more than 135 years.

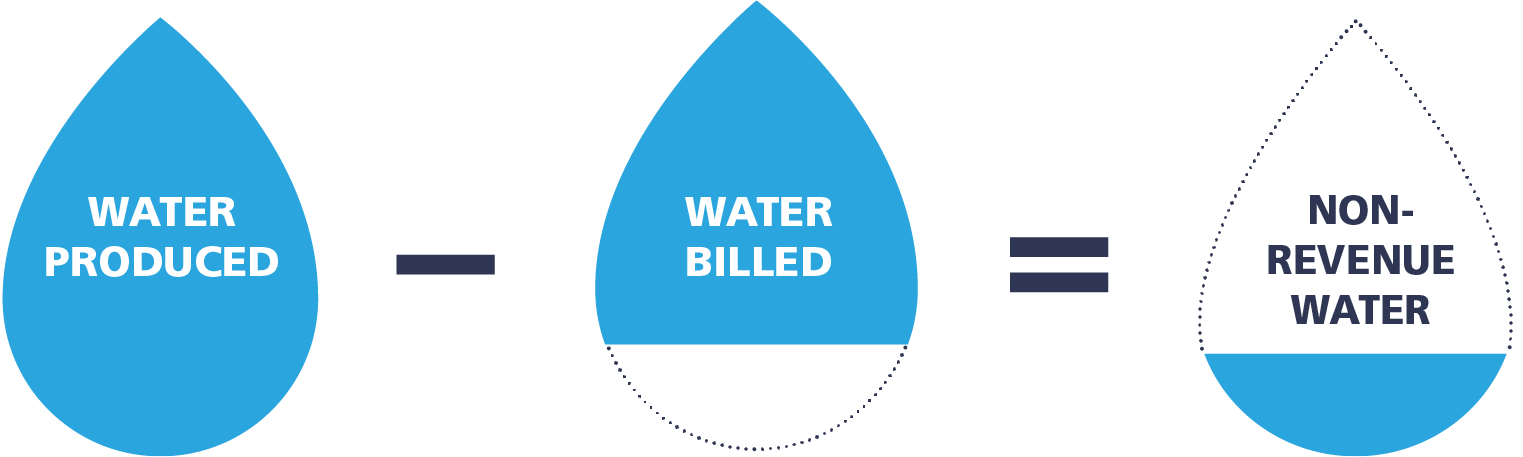

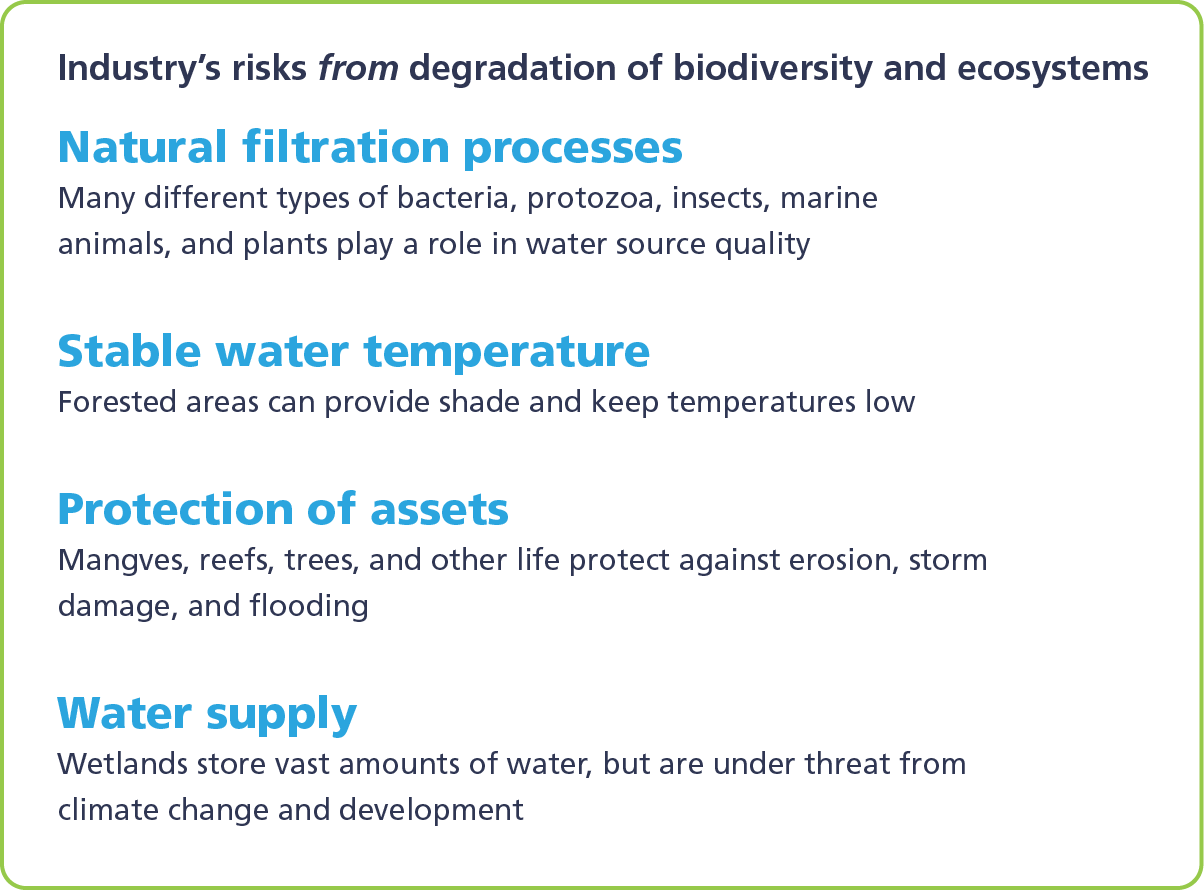

Fresh water is a limited resource on our planet, and we need to manage it responsibly.

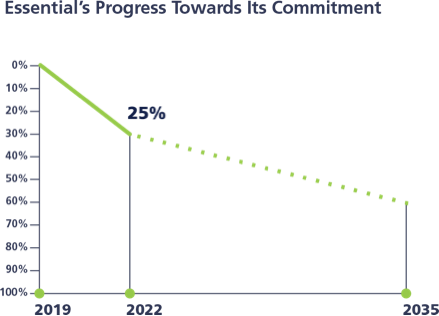

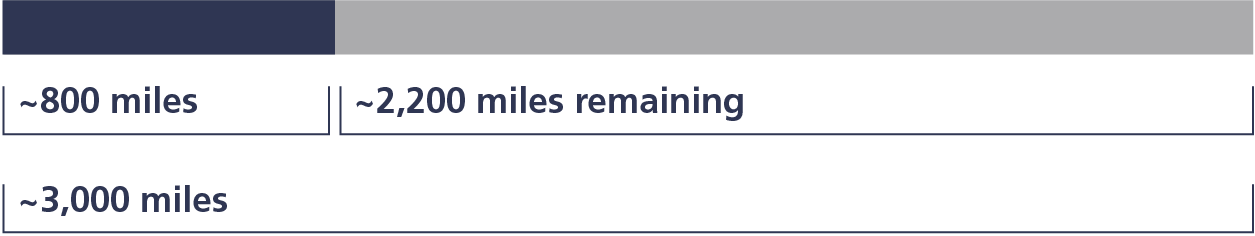

Through conservation and stewardship, Essential helps to safeguard water security for future generations. Essential also strives to operate a safe, resilient gas distribution system that provides affordable and reliable energy to our customers. Across our operations, we have participated in environmental conservation and stewardship with many community partners to preserve and protect sensitive lands, plant thousands of trees, manage invasive species, reintroduce and reestablish native species and protect habitats. We have also released an ambitious emissions reduction target with concrete actions outlined to achieve this goal.

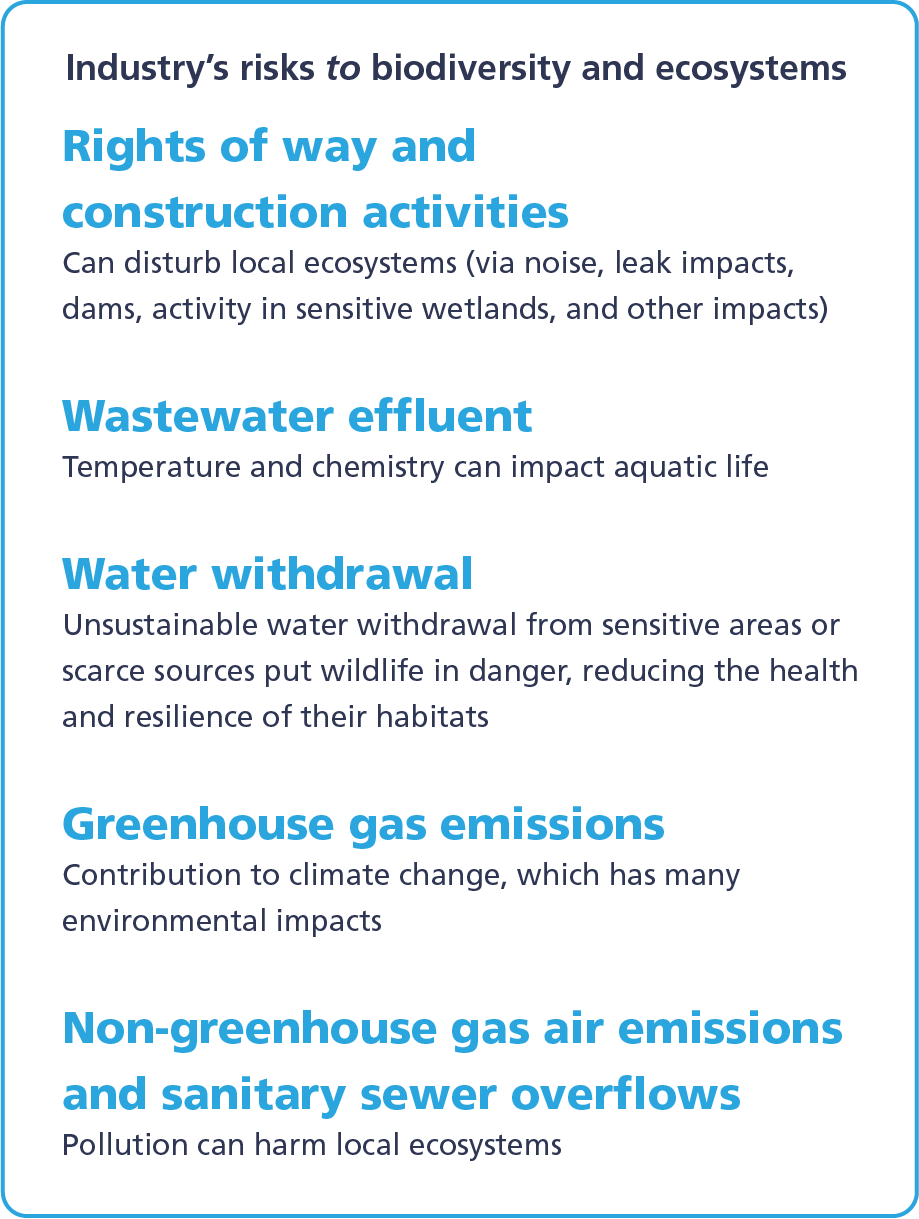

Our Sustainability and Environmental Policy outlines the ways we apply our mission throughout our environmental profile. Our actions reflect the values that permeate our team and operations around the country. We ensure environmental stewardship remains a priority for company management by factoring several benchmarks into executive compensation. This means water compliance, wastewater compliance, gas pipeline replacement and minimizing gas leaks all contribute an equal weighting to executive leadership.

In this report, we expand on our commitment to present our stakeholders with some of the most detailed and transparent disclosures in the utilities industry. Whether we are speaking about water quality, gas system reliability, greenhouse gas emissions or our waste program, we aim to provide rigor around both quantitative disclosure and qualitative explanations and context.

Recent Environmental Highlights

Environmental Management System

As a large and diversified utility, Essential’s strong environmental management system is critical to our operations.

Our Environmental, Health and Safety management program identifies, prioritizes, communicates, addresses, mitigates and manages risks to ensure safe and reliable service for our customers. These areas are benchmarked through performance and risk reporting coordinated anywhere from the unit and state level up to the Chief Environmental, Safety and Sustainability Officer, the Chief Operating Officer and quarterly, the Board of Directors.

The Compliance Assurance Program (CAP) is Essential’s Environmental Management System (EMS). Each Essential company has designated personnel (environmental directors, environmental managers, environmental specialists, etc.) who are responsible for supporting the CAP while focusing on environmental compliance. As part of our alignment with the elements of ISO 14001, Essential’s CAP is founded on the concept of “Plan-Do-Check Act.”

Plan-Do-Check-Act

Plan |

Do |

Check |

Act |

| Policy | Corporate Programs | Compliance Checking | Root Cause Analysis |

| Benchmarking | State SOPs | Water Quality Tracking | Corrective Actions |

| Target Setting | Communications | CAP Meetings | Programmatic Changes |

| Regulatory Register | Training | Auditing | External Support |

| Risk Analysis | Emergency Planning | Management Reviews | Peer Reviews |

In addition to routine communications and activities, special CAP meetings are held multiple times per year for each state and business and are attended by presidents, vice presidents, directors, managers and operations staff from corporate and state compliance, operations and engineering. Topics covered in these meetings include compliance metrics, water quality, environmental events, regulatory and company hot topics, and system/project review. Actions, events, activities, documents and records are tracked and managed in our Environmental Health and Safety Data Management System software.

Additionally, Essential is in the process of implementing a water quality data management system across its water and wastewater utilities. This will ultimately serve as the central repository for all water and wastewater quality data, providing company-wide access to trends and early identification of developing issues.

BUSINESS CONTINUITY AND EMERGENCY PREPAREDNESS

Business Continuity and Emergency Preparedness

Business Continuity Plan - Water and Wastewater Operations

The purpose of our business continuity plan is to keep all our water and wastewater plants and operating facilities online and in compliance with applicable regulatory requirements. This plan also promotes appropriate maintenance of distribution systems, uninterrupted water supply and wastewater processing and the health and welfare of our employees, customers and their families.

Essential’s business continuity plan for water and wastewater operations covers the following key areas:

- Worker safety

- Permit compliance

- Sustainability of critical operations

- List of primary and back up operators (licenses), as well as information pertaining to who has been trained and prepared to step in during cases of emergency

- Modification to normal and routine business workflow

- List all facilities, along with their classifications and licenses

- Pandemic trigger points, assessed on a three-tier level system

Business Continuity Plan - Gas Operations

Similarly, Essential’s gas utility also has a detailed emergency response plan that outlines the procedures, guidelines, organizational support and communication to respond to natural gas emergencies on pipeline systems, customer service outages or other natural disasters that present potential hazards to the public, property or environment. The purpose of this emergency response plan is to keep all our gas facilities and systems online and in compliance with regulations and regulatory requirements. The plan is reviewed and updated annually with all operating personnel, and tabletop exercises and emergency simulations are conducted to provide the general knowledge and preparedness to respond to these types of events.

Eastern Seaboard Hurricane Plan

Our Eastern Seaboard Hurricane Plan is applicable to New Jersey, North Carolina, Pennsylvania and Virginia water and wastewater operations. This plan is updated annually, and its purpose is to aid in the mitigation, preparedness, response and recovery from hurricane and severe storm conditions that threaten or impact Essential’s community water system facilities. It also includes intracompany mutual aid. A similar plan is used in Texas.

Once a hurricane’s path has been identified with a probability that it will affect any of our water systems, it is the responsibility of the state presidents, or their designees, to initiate interstate company communication and preparation for the impending hurricane or severe storm. We use an EPA Hurricane Incident Action Checklist for water utilities as a template to assist the states. It includes individual checklists which should be completed for the start of hurricane season, before an impending hurricane and after a hurricane.

Local and national contractors and vendors are listed to facilitate appropriate level of coordination prior to any event. Regions are required to contact their local contractors and vendors first, with national contractors and vendors to follow.

Operations teams work with communications managers when there is a need to release any type of public notification to Essential customers to ensure they are made aware of any potential disruptions to service.

Essential’s Business Continuity Journey

To help support our organization’s business continuity, we have kicked off a multi-year effort to achieve the following:

- Increase Essential’s preparedness for high impact uncertainties and its response and recovery

- Improve upon Essential’s prevention capabilities and its ability to achieve operational resiliency

- Develop Essential’s proactiveness as it relates to mitigation and management measures taken to decrease impact

The first portion of this work, completed in 2021, developed an integrated Incident Management Plan and a Crisis Communication Plan for Essential Utilities, embedding our existing business continuity plans as sub-plans. The Incident Management Plan memorializes the processes, procedures and protocol necessary for responding to a business interruption occurrence or any other high- level uncertainties. The plan concentrates on safety, including the protection of life, assets and environment. Due to a change in personnel, the plan is currently under review. When updated, we will develop and exercise complimentary training for the new plan to ensure effective execution.

Once developed, these corporate-level plans will be updated annually for content and contacts.

The second portion of the work is a long-term initiative that will deliver new operation-specific Business Continuity Plans. These will be master plans for operational resiliency and recovery following a business interruption occurrence.

A complementary goal of this effort is to standardize the frequency and cadence of testing and simulation exercises across the organization. Today, these are performed throughout the organization but frequency and cadence varies across state operations.

Managing Water and Wastewater Systems

Managing Water and Wastewater Systems

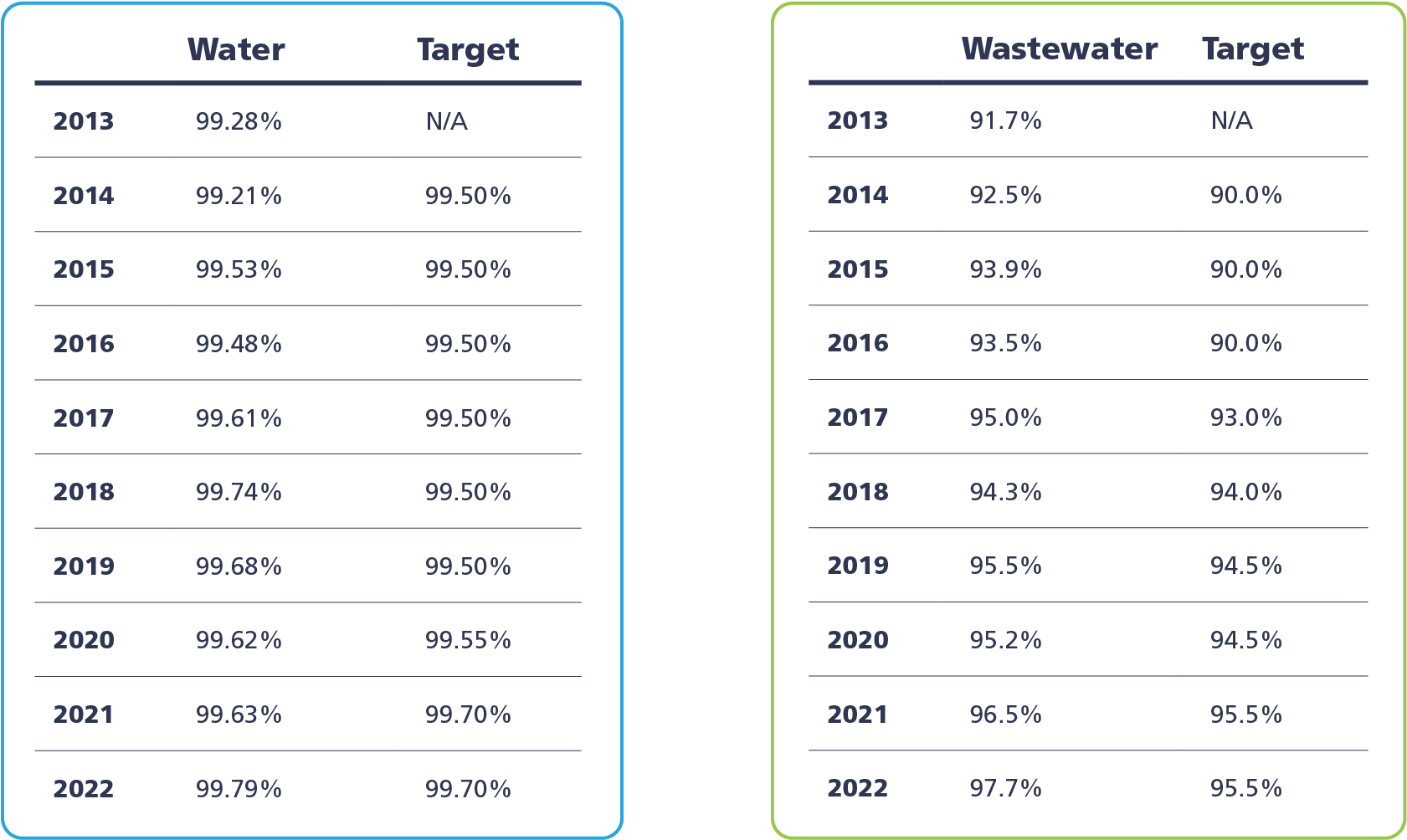

Essential provides clean, safe, reliable water and wastewater services in the communities it operates. As a publicly regulated utility, Essential must follow all federal and state water compliance regulations, including those from the Environmental Protection Agency (EPA). We work hard to meet our goal of operating with exceptional compliance with the Safe Drinking Water Act. Across the 1,500+ water systems we own and operate, this compliance allows us to provide safe and reliable drinking water for all customers.

We are committed to providing reliable and efficient wastewater treatment and strive to operate our 200+ wastewater systems in compliance with the Clean Water Act. Most wastewater ultimately ends up back in local rivers or streams, so it is vital that Essential treats all wastewater before it is discharged.

At Essential, we have the technical expertise and experience to offer superior wastewater services that meet all environmental and public health standards. We are continuously modernizing wastewater treatment methods, ensuring our systems protect the surrounding environment and adhere to current standards. Our goal is to return water to our streams and rivers cleaner than when we took it – after a thorough treatment process that includes screening, primary clarification and biological treatment. Beyond returning water to the source, we operate several plants that feature a wastewater reuse program that provides safe and treated irrigation water to local businesses, such as golf courses. This prevents discharge to streams and efficiently reduces demand for freshwater supply. We continue to proactively identify opportunities for wastewater reuse.

DRINKING WATER

- 1,512 Water systems

- ~0.9 Million Connections

- 86.9 Billion gallons of total water production

WATER SOURCES

- 54% Surface

- 37% Ground

- 9% Purchased from other systems

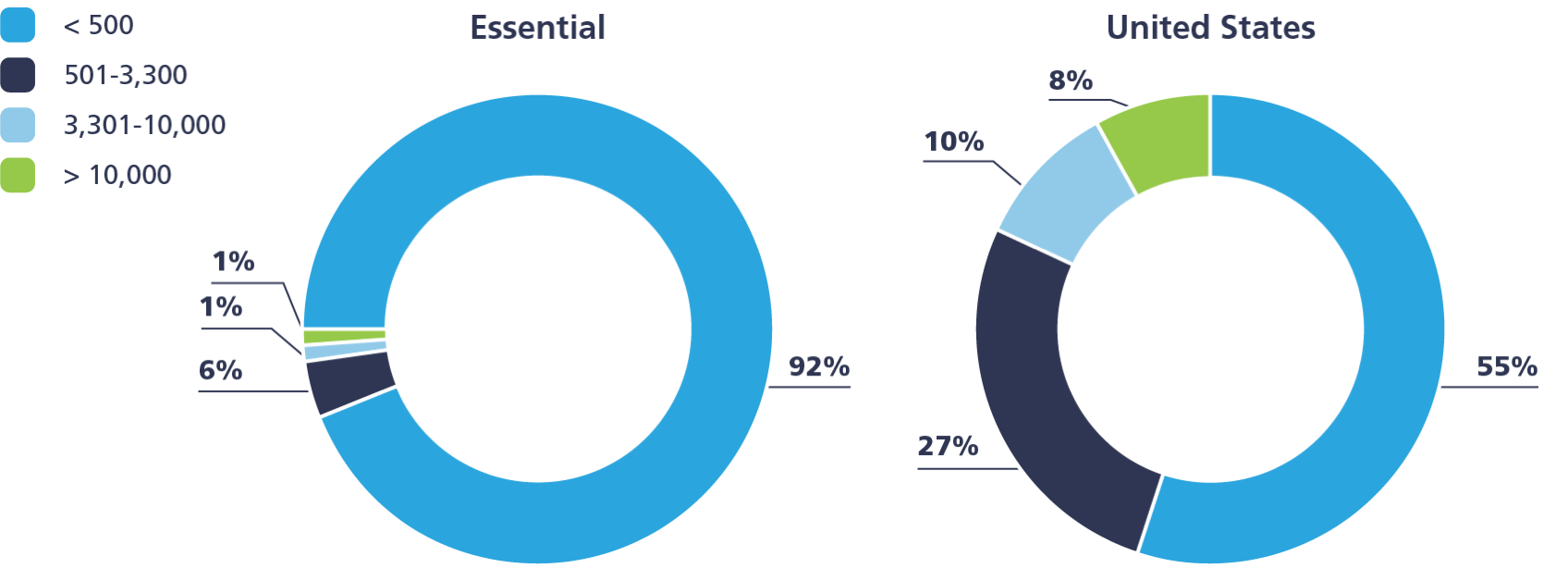

Size of Drinking Water Systems

Measured by number of connections and presented as percent of water systems

WASTEWATER

- 230 Wastewater systems

- ~0.2 Million Connections

- 11.2 Billion gallons treated

- 64.7% of capacity*

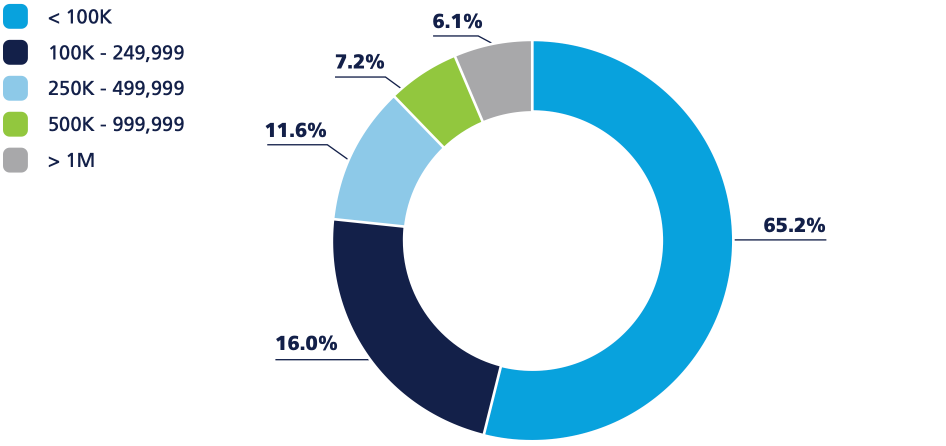

Size of Essential's Wastewater Treatment Plants

Measured by gallons of permitted capacity and displayed as percent of wastewater treatment plants

*17.3 billion gallons of permitted capacity